Check & Bleeder Valve

Home /

Products

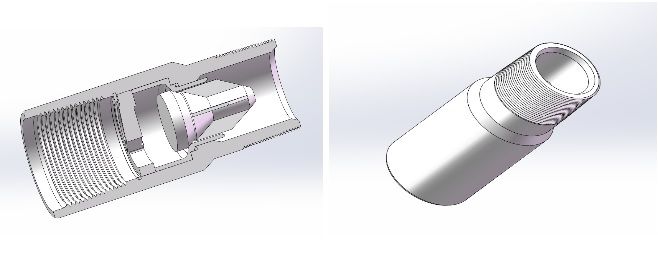

Check Valve Description

Check valves are recommended for use in the tubing string for ESP system to keep the discharge-tubing full of fluid when the pump is off. The check valve allows for a full column of fluid/head for the pump to restart against, thereby; eliminating the possibility of damage to the pumping system that may be attributed to insufficient head. It will also eliminate fluid from flushing back through the pump enabling a quicker restart. The check valve is run generally two or three joints above the pump. If the check valve is not installed, the pump should not be started until the fluid column has had a chance to equalize, eliminating the chance for a twisted shaft in the pump, or a burned cable or motor.• Check valves are recommended for use in the tubing string for ESP system to keep the discharge-tubing full of fluid when the pump is off. The check valve allows for a full column of fluid/head for the pump to restart against, thereby; eliminating the possibility of damage to the pumping system that may be attributed to insufficient head. It will also eliminate fluid from flushing back through the pump enabling a quicker restart. The check valve is run generally two or three joints above the pump. If the check valve is not installed, the pump should not be started until the fluid column has had a chance to equalize, eliminating the chance for a twisted shaft in the pump, or a burned cable or motor.

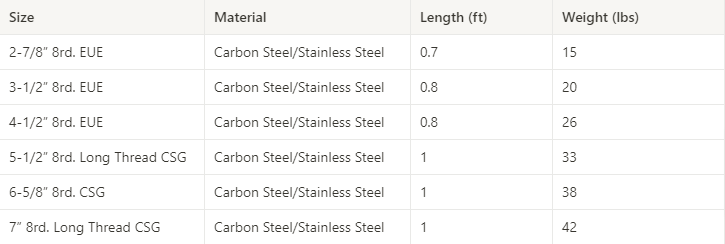

Check Valve Specification

Bleeder Valve Description

The bleeder Valve is normally installed one joint above the check valve. The Bleeder Valve or Drain Valve has a small drain plug inside it. Breaking the plug will allow the tubing to drain well fluid from tubing to anulus area.

Bleeder Valve Description

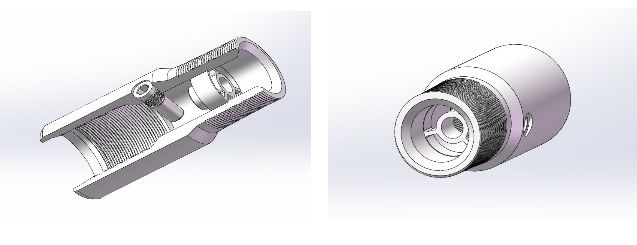

Combination Check Valve & Bleeder Valve Description

Combination bleeder and check valve used in application where check valve and drain valve are needed to protect ESP and prevent pulling wet tubing

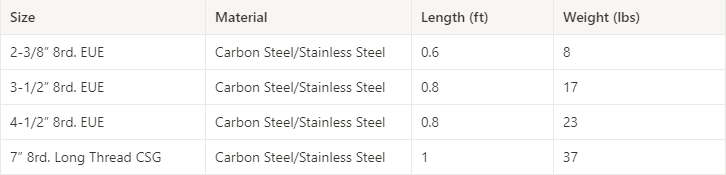

Combination Check Valve & Bleeder Valve Specifications